We would be making the ckt in the same way as we did for the IR led detector ckt , but we wuld be using LDR for our detection purpose , (IR cant be used as they catch only IR waves) , and in place of the IR transmitter we wuld be using three leds of red, blue and green.

WORKING:

Light up each of the leds one at a time , ie red , then blue n green , if the obstacles are of red blue and green colour then you wuld be getting different outputs ( REMEMBER VIBGYOR) .

With micrcontrollers , lit up the red led if there is reflection take the ADC reading

do the same for other leds and take thier ADC reading , we will know which colour its detecting.

One sensor wuld be lit up always .

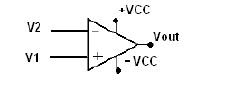

Use a potentiometer with each of the LEDs to get a better reading , as there wuld be slight color difference .The circuit will be the same as for the ir sensor which i have explained in my previous post , with litlle changes .Hope u njyd it

FIGURE 1.

FIGURE 1.

HERE IS THE SIMPLE MANUAL CONTROL OF U R BOT USING DPDT SWITCH JUST CONNECT THESE SWITCHES TO THE MOTOR AS SHOWN BELOW AND TATS IT ZOOOOOOOOM U CAN C U R BOT RUNNING

HERE IS THE SIMPLE MANUAL CONTROL OF U R BOT USING DPDT SWITCH JUST CONNECT THESE SWITCHES TO THE MOTOR AS SHOWN BELOW AND TATS IT ZOOOOOOOOM U CAN C U R BOT RUNNING